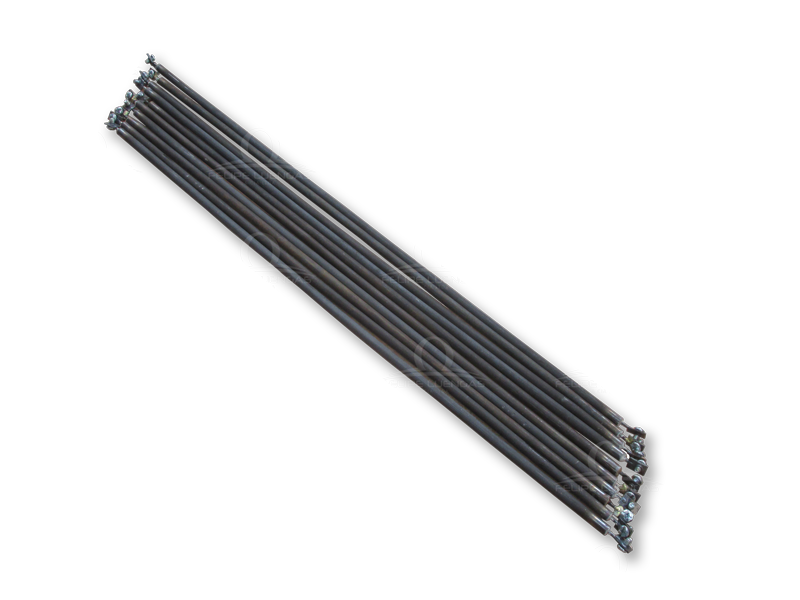

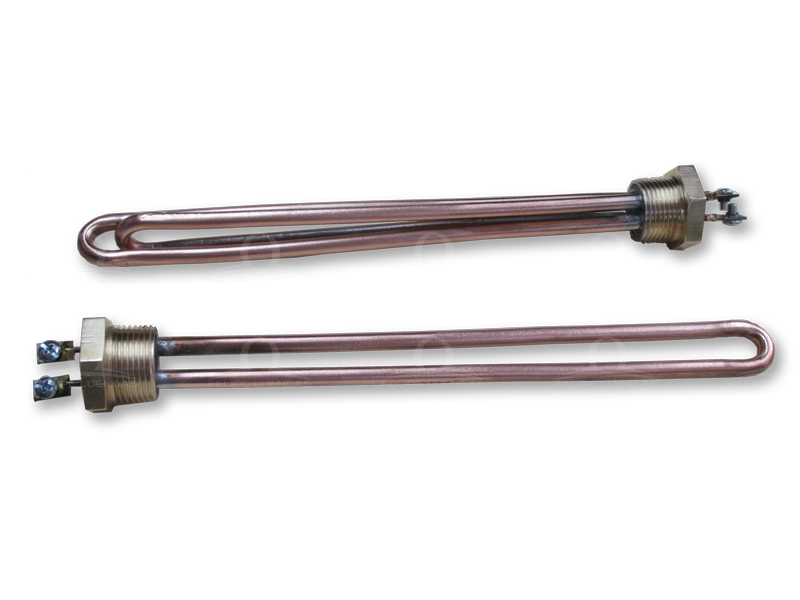

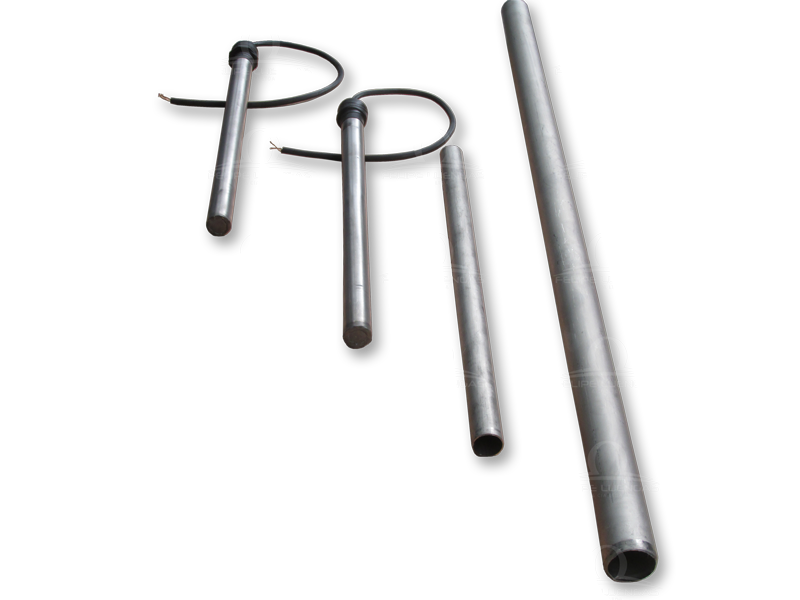

The term "Tubular Heater" generally refers to heating elements that are composed of a spiral of resistive wire insulated by magnesium oxide (MgO) from a sheath that in our case is 316 stainless steel, copper or titanium. They are constructed in diameters 1/4”, 5/16”, 3/8”, 7/16”, 1/2”, 5/8” for stainless steel or copper and 1”or 1 1/2” for titanium, according to the power density, length and shape that is required.

Characteristics:

- Robust construction.

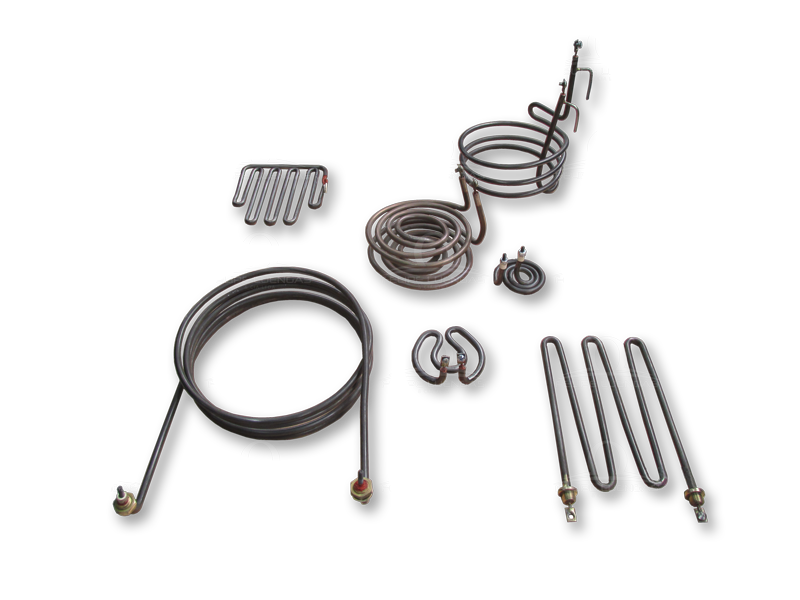

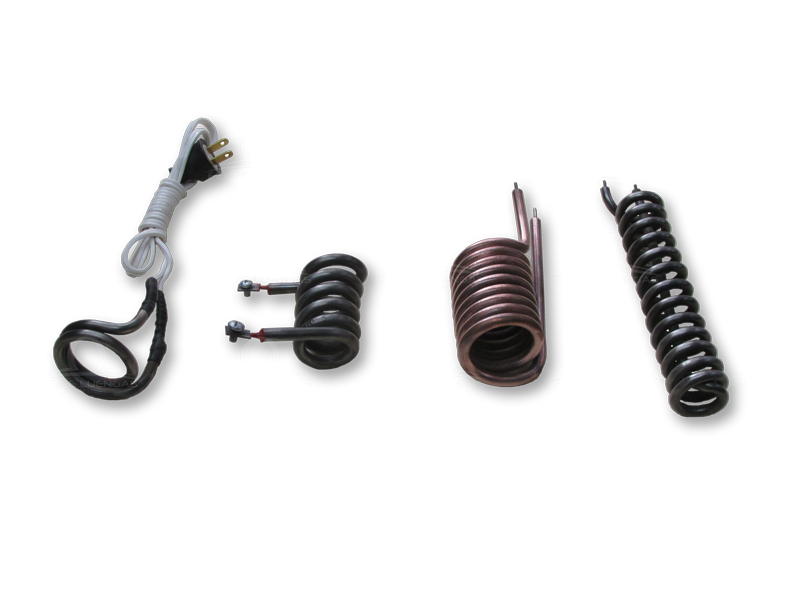

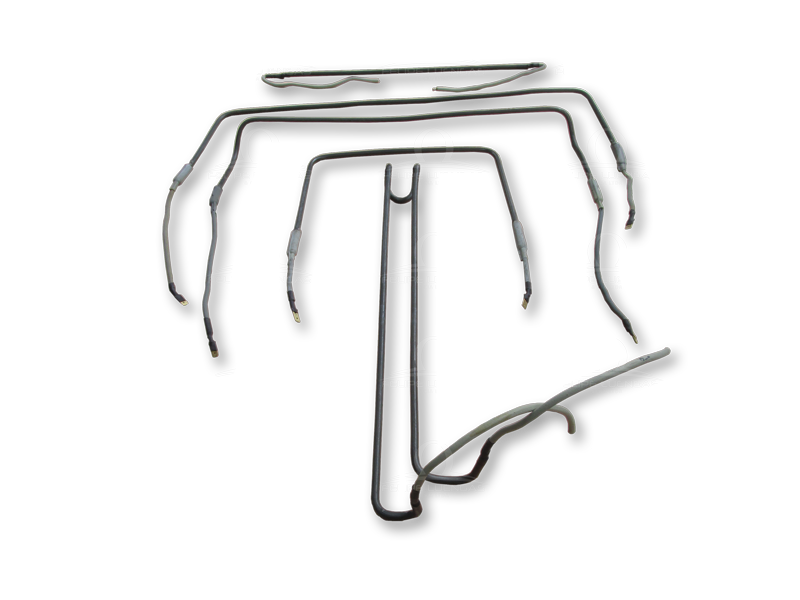

- They can be figured in almost any form.

- Excellent electrical insulation, good dielectric strength and low leakage currents.

- Low maintenance costs.

- Temperatures below 700 ° C.

- Transfer heat in any of the three forms of transfer according to the application.

Applications:

- These types of heaters are very versatile and are widely used in heating gases, solids and liquids.